Regmiks Steel Fiber Wire

Regmiks steel fiber, macro and micro synthetic fibers are concrete reinforcement materials that provide certain advantages compared to conventional reinforcements together with concrete. Regmiks steel fiber wire, macro and micro synthetic fiber wires are made of different wire materials designed to increase temperature and shrinkage crack control, enhanced flexural reinforcement, improved shear strength and crack resistance of concrete. The fibers are sometimes referred to as structural fibers and are intended to bear loads and are therefore used in some non-structural applications to replace conventional reinforcement as well as to minimize and/or eliminate both early and late age cracks.

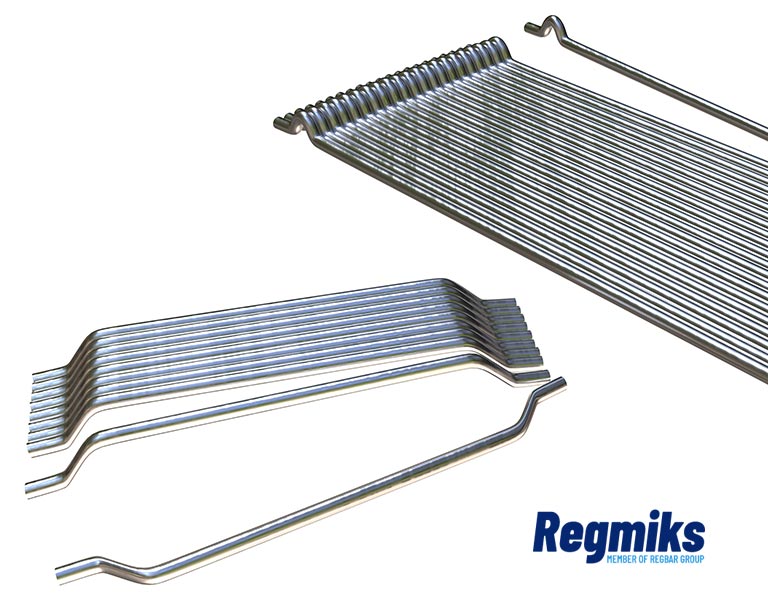

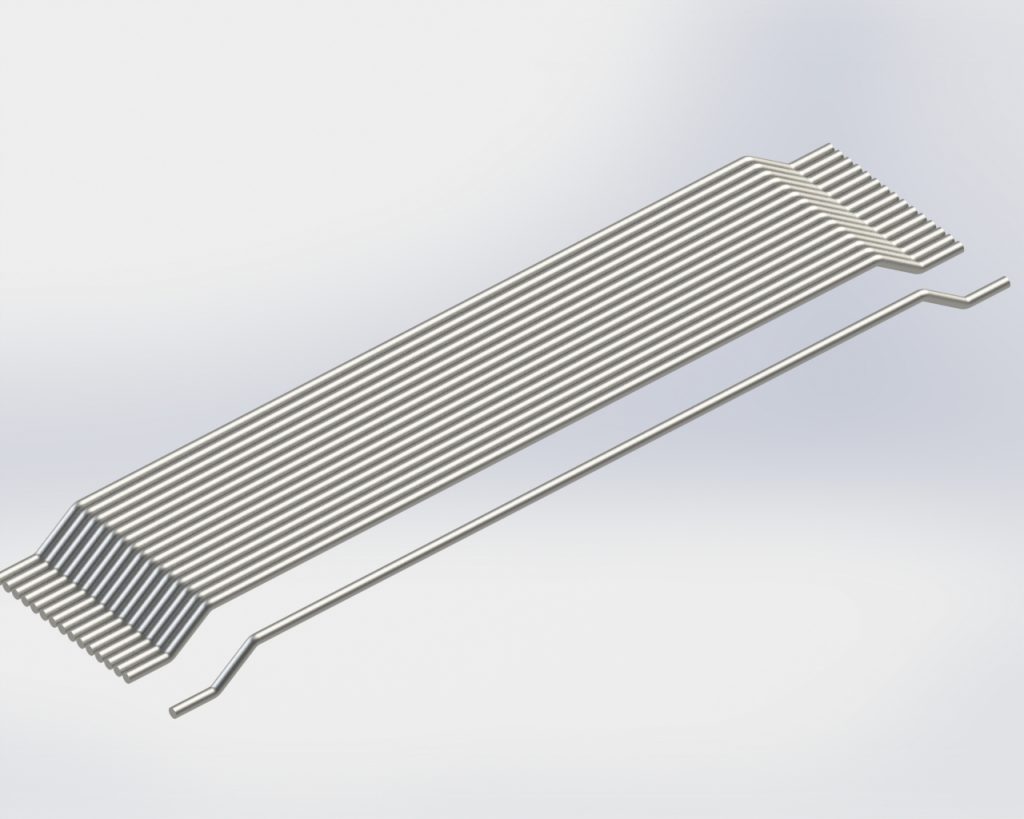

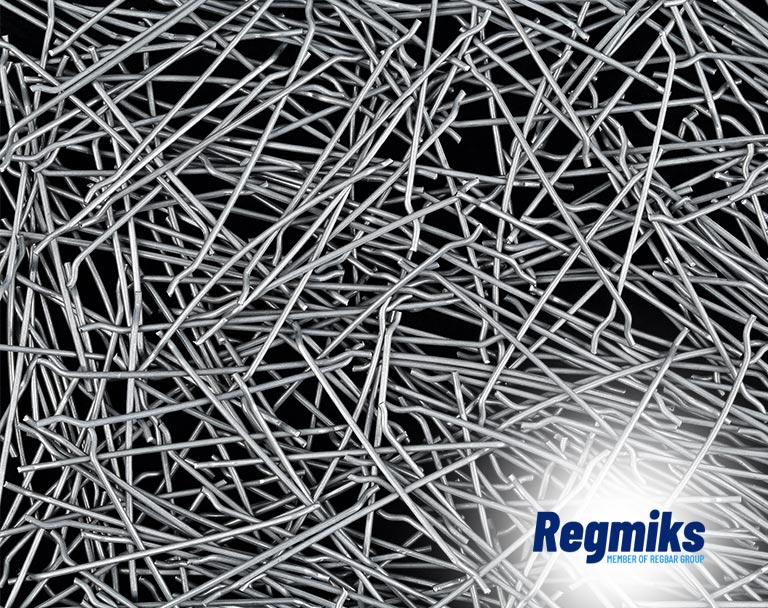

Steel Fiber Wire

Steel fibers and rebar have some things in common. Both are made of steel. Both are used to reinforce concrete and both can be found in floor slabs. Because of these common features, it’s tempting to think that the two products are basically the same, just different in size. Maybe a steel fiber is just a very small reinforcing bar.

- 100% Quality Production

- Production in Quality Standards

- Support after sale

Usage & Advantage

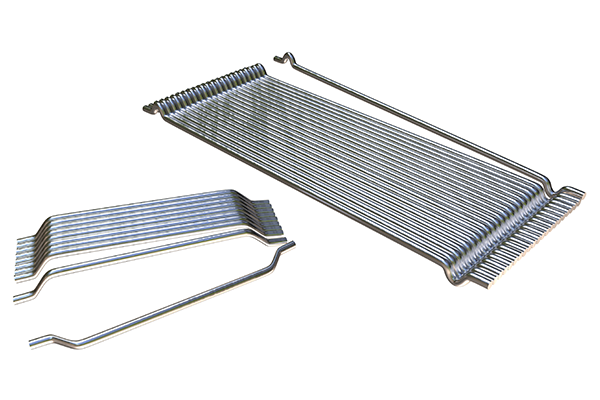

Regmiks is generally used to prevent cracking, increase impact resistance, resist dynamic loading and material fragmentation. Regmiks can be used without any additional reinforcement in almost any application where bending stresses are not overwhelming, for example beams. Steel fiber wire is used in tunnel engineering, hydro structures, airport and highway pavements and other construction areas that need strong and high performance structures, especially with the high performance they provide. Normal concrete is brittle, while fibrous concrete has priority over normal concrete due to its higher strength and capacity to prevent breakage. The advantages of steel fiber reinforced concrete structures over normal concrete can be summarized as follows:

All concrete has microcracks and some appear earlier. When concrete is subjected to tensile stress, which can be caused by drying shrinkage, thermal shrinkage, or applied loading, some microcracks expand and lengthen and become cracks that you can see. Not every microcrack grows big enough to become a crack; most of them are small.

Steel Fiber Wire Advantages

- HIGH IMPACT RESISTANCE, TENSILE, BENDING AND STAPLE STRENGTH

- HIGH LOAD CARRYING CAPABILITY

- HIGH RESISTANCE, GOOD DUCTILITY

- Increase the limits of your concrete with tensile strength ranges of 100 – 285 ksi

- Reinforce at multiple angles as opposed to the traditional practice of welded wire mesh and rebar sheathed

- It spreads the energy of these forces to the entire concrete, reducing the damage caused by impact and abrasion.

- increases post-crack flexural strength by supporting a load even after a crack has formed.

- Flexural Strength: flexural strength can be increased up to 3 times compared to conventional concrete.

- Eliminate shrinkage cracks.

- Increase in transverse and longitudinal joint space.

- Increased load bearing capacity of concrete to reduce concrete slab thickness.

- Concrete cracks do not reduce the load capacity.

- Increased durability.

Preparation of Steel Fiber Reinforced Concrete Mixture and Usage Areas

As with any other type of concrete, the mixing ratios for Regmiks are based on strength, workability, etc., to the requirements of the particular job. in terms of. Various procedures are available for proportioning Regmiks mixes, emphasizing the workability of the resulting mix. However, there are some Regmiks specific considerations.

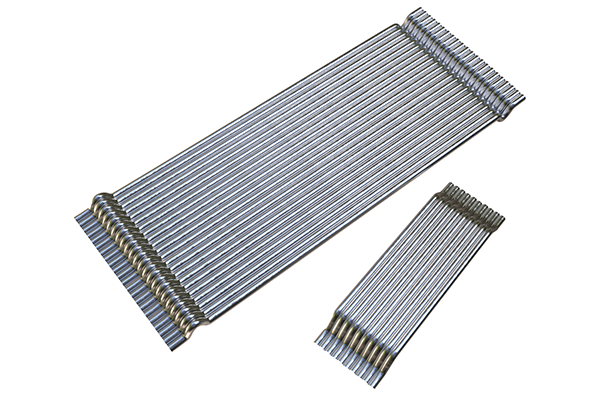

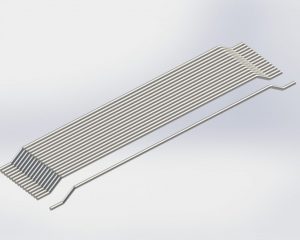

Steel fiber reinforced concrete is a composite material with fibers as additional components, randomly dispersed in small percentages, that is, from 0.3% to 2.5% by volume in plain concrete.

Regmiks products are produced by adding steel fibers to the components of the concrete in the mixer and transferring the concrete to the molds. The product is then compacted and cured using conventional methods.

Technical Document

For the comparison of steel wire and micro fiber wire

First of all, Calculation values for Fiber Reinforcements are calculated in ACI 360R10 with the following formulas. These calculation values are determined depending on Re3 (residual strength) and I am sharing it with you in the appendix.

Fiber reinforcement and Regmiks residual strength results as a result of the experiment conducted at Pontificia Universidad Católica University are as follows;

The relevant test results show that the energy absorption capacity of 1kg/m3 Fiber reinforcement is approximately equivalent to 7kg/m3 Regmiks.

| No: | Material | Type | Fiber quantity (kg/m3) | Air Ratio % | Unit Weight (ton/m3) | Crash Amount(mm) |

| 1 | Fiber | 54 mm | 2 | 2,9 | 2,35 | 6,5 |

| 2 | Fiber | 54 mm | 4 | 3 | 2,33 | 6 |

| 3 | Fiber | 54 mm | 6 | 2,9 | 2,32 | 7 |

| 4 | Fiber | 54 mm | 8 | 3 | 2,3 | 6,5 |

| 5 | Steel Wire | 30 mm | 20 | 2,9 | 2,35 | 5,5 |

| 6 | Steel Wire | 30 mm | 30 | 3 | 2,37 | 6,5 |

| Plain Concrete | – | 3 | 2,33 | 8 |